MOREL Franz Enno : 3D printing of silica based microsensors for photonic and sensing applications

Résumé de thèse :

The boom in additive manufacturing technologies, also known as 3D printing, opens the door towards new possibilities in various fields of research and industry. Its advantages lie in the rapid development of prototypes and complex structures, previously hard to achieve with the existing methods. In this context, two-photon polymerization (2PP) 3D printing technology play an important role by providing access to additive manufacturing on a nano- to micrometre scale. With the help of certain materials, this process can be tailored to suit specific applications, in particular for the manufacturing of optical components [1]. The use of this manufacturing process opens up a wide range of new possibilities in the field of optical sensors and photonics, from the rapid prototyping of new sensors to the creation of so-called "lab-on-fiber" or "lab-on-tip" devices. In addition, 2PP can also be integrated with the existing sensor technologies i.e. Fiber Bragg gratings, to combine the sensing abilities of a fiber. This new technology could have applications in the fields of aeronautics, biology and detection in extreme environments (i.e. radiation, heat). In this context, the aim of this thesis is to develop silica-based sensors at the tip of optical fibers that can be used for monitoring the change of pressure [2] or temperature in the vicinity of the fiber.

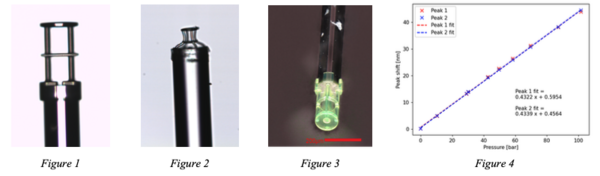

During the first part of the thesis, I have observed that it is possible to print a Fabry-Perot interferometer on the tip of an optical fiber (SMF-28) using a sol-gel resin (Fig. 1), developed by the PhLAM and the resin has been subsequently transformed into silica after an annealing process (Fig.2). This interferometer takes the shape of a reflecting face supported by several pillars. Although this process has benefits as the silica structures are more resistant to heat than polymer, the resin used during the printing process, shrinks during annealing due to the densification of the sol-gel. Therefore, the printed structure is detached from the fiber end. The aforementioned problem required the development of a specific grip method to hold the desired object to the fiber tip, which is currently under investigation. Furthermore, a similar interferometer structure was made out of polymer (Fig. 3), instead of sol-gel and it has been found out that this could be used for the measurement of pressure. It has already been observed that the structure responses linearly to pressure changes in the range of 1 to 100 bar (Fig. 4).

As a next step of this thesis, it is further planned to use a silica based Fabry-Perot interferometer for measuring the pressure changes. As well as combining a Fabry-Perot and Fiber Bragg Grating on the same fiber for simultaneous pressure and temperature measurement with a single fiber.

References

-

D. Gonzalez-Hernandez, S. Varapnickas, A. Bertoncini, C. Liberale, M. Malinauskas, Micro-Optics 3D Printed via Multi-Photon Laser Lithography. Adv. Optical Mater. 2023, 11, 2201701.

-

Heming Wei, Maoqing Chen, and Sridhar Krishnaswamy, "Three-dimensional-printed Fabry–Perot interferometer on an optical fiber tip for a gas pressure sensor," Appl. Opt. 2020, 59, 2173-2178.

Doctorant : MOREL Franz Enno

Directeur de thèse : DOUAY Marc